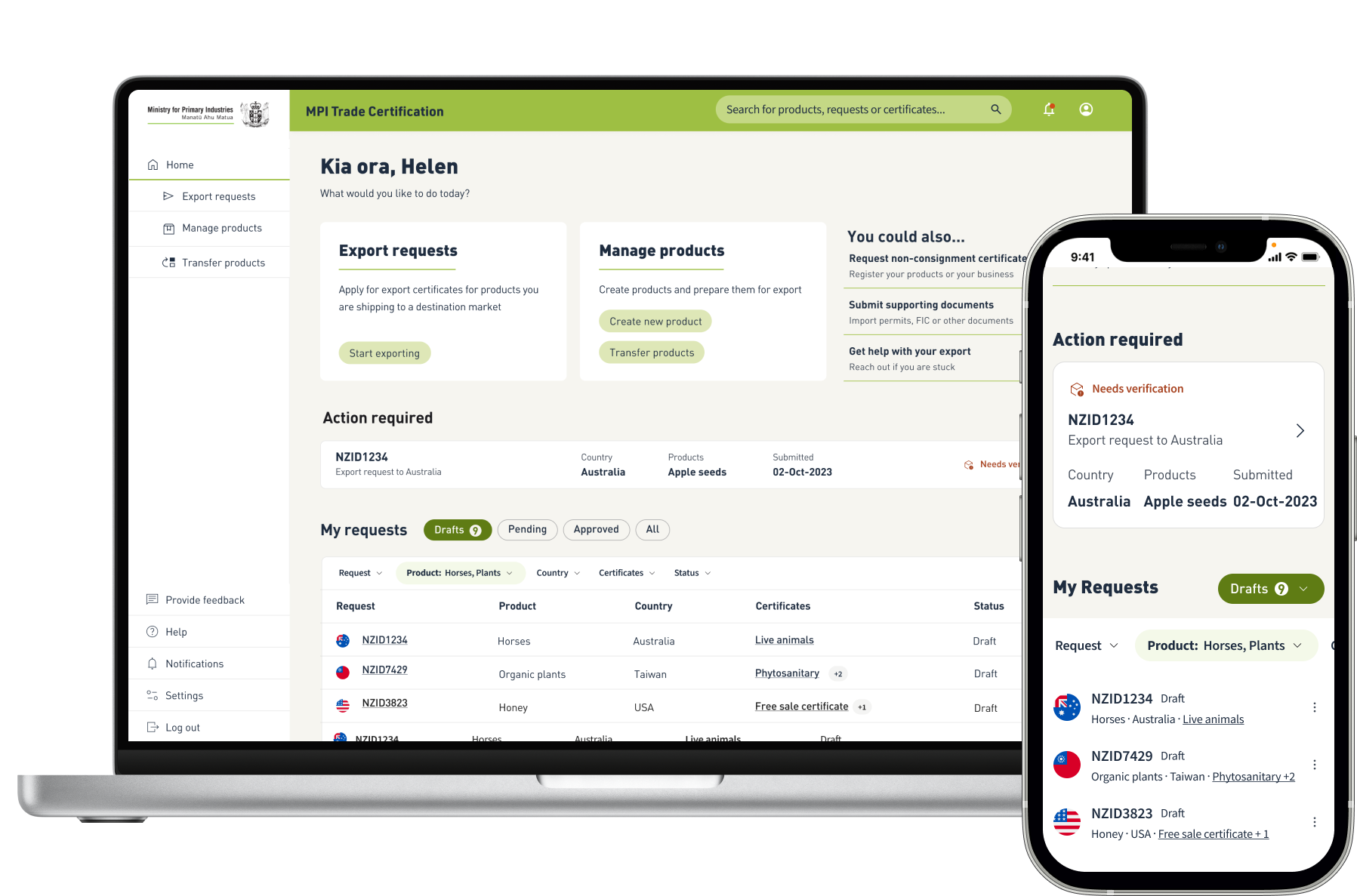

Modernising Export for Kiwi Businesses

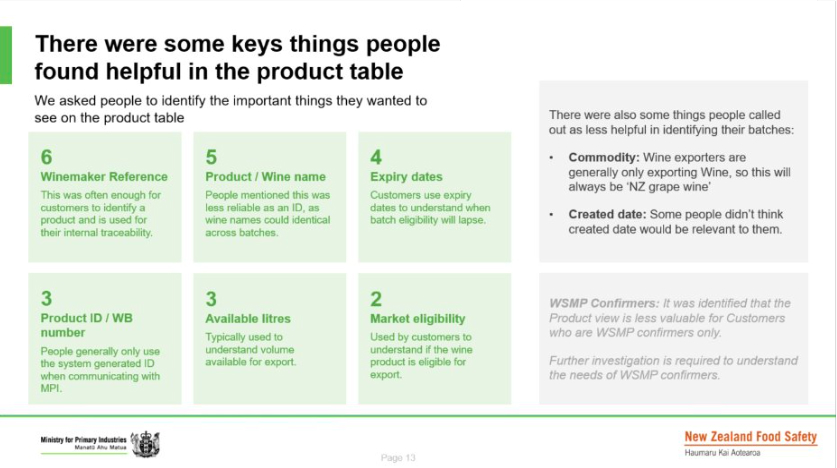

Every day, New Zealand exporters send off some of our finest wine, meat, dairy to the world. But behind each shipment is a maze of paperwork, outdated systems, and manual checks. For many exporters, certification as the final green light before a product leaves the country has been a stressful experience.

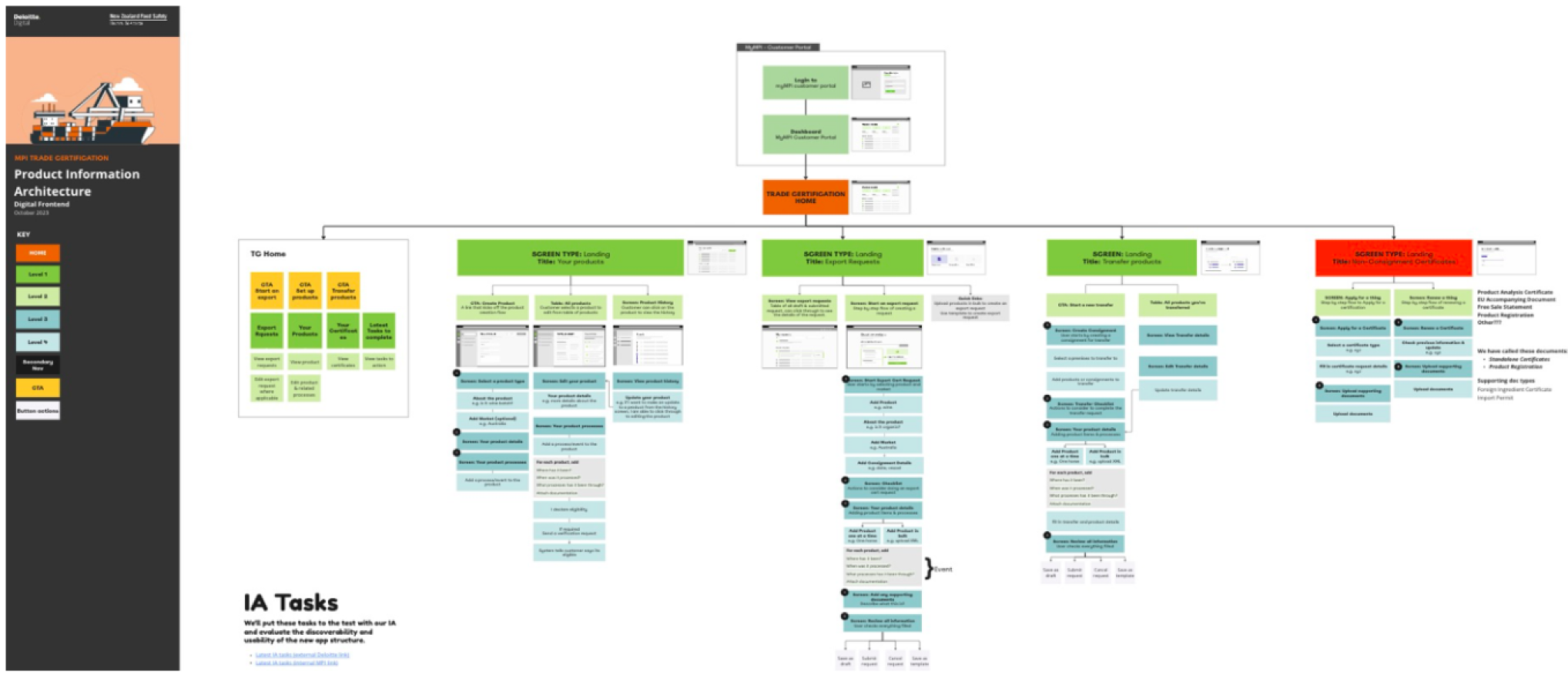

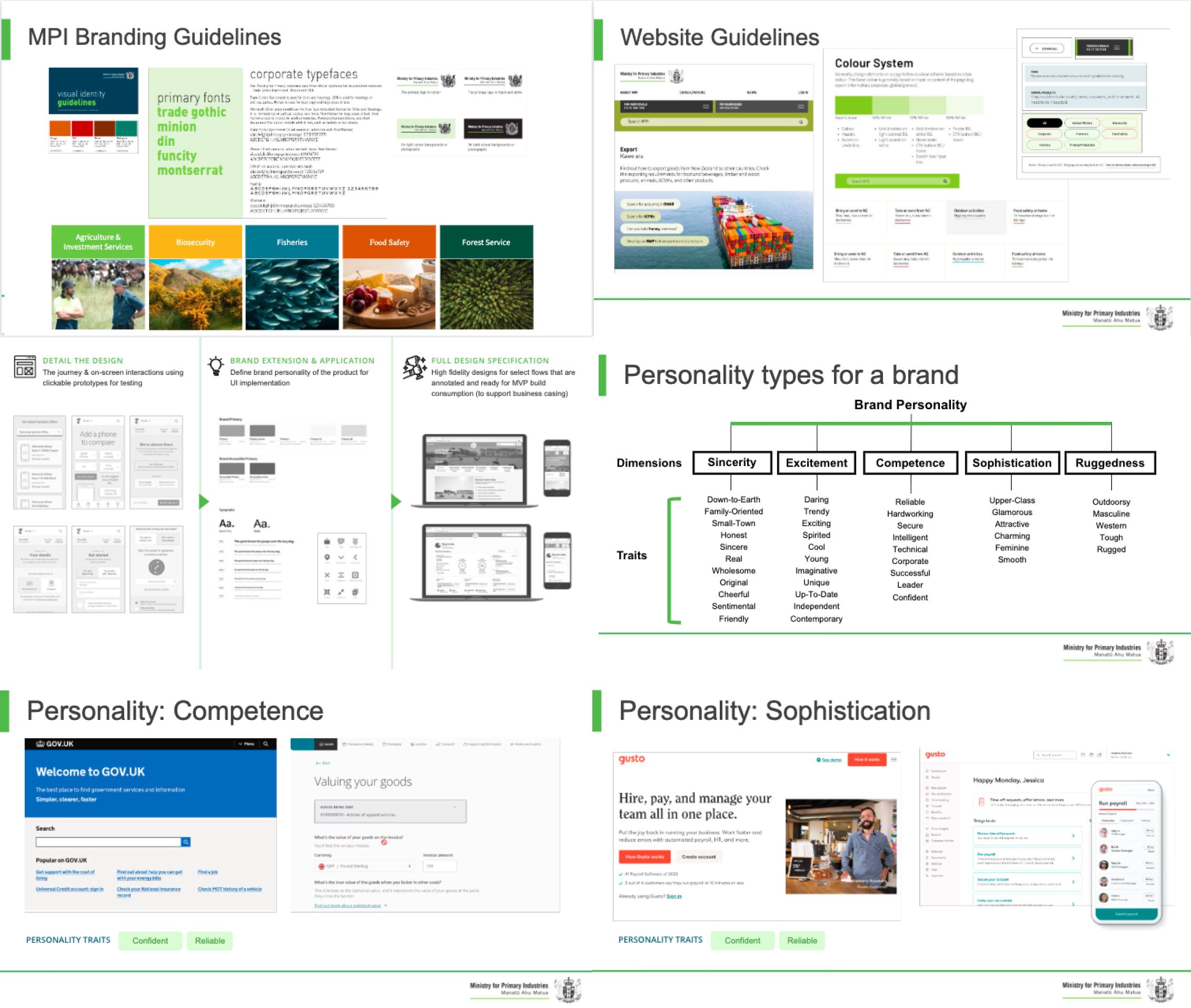

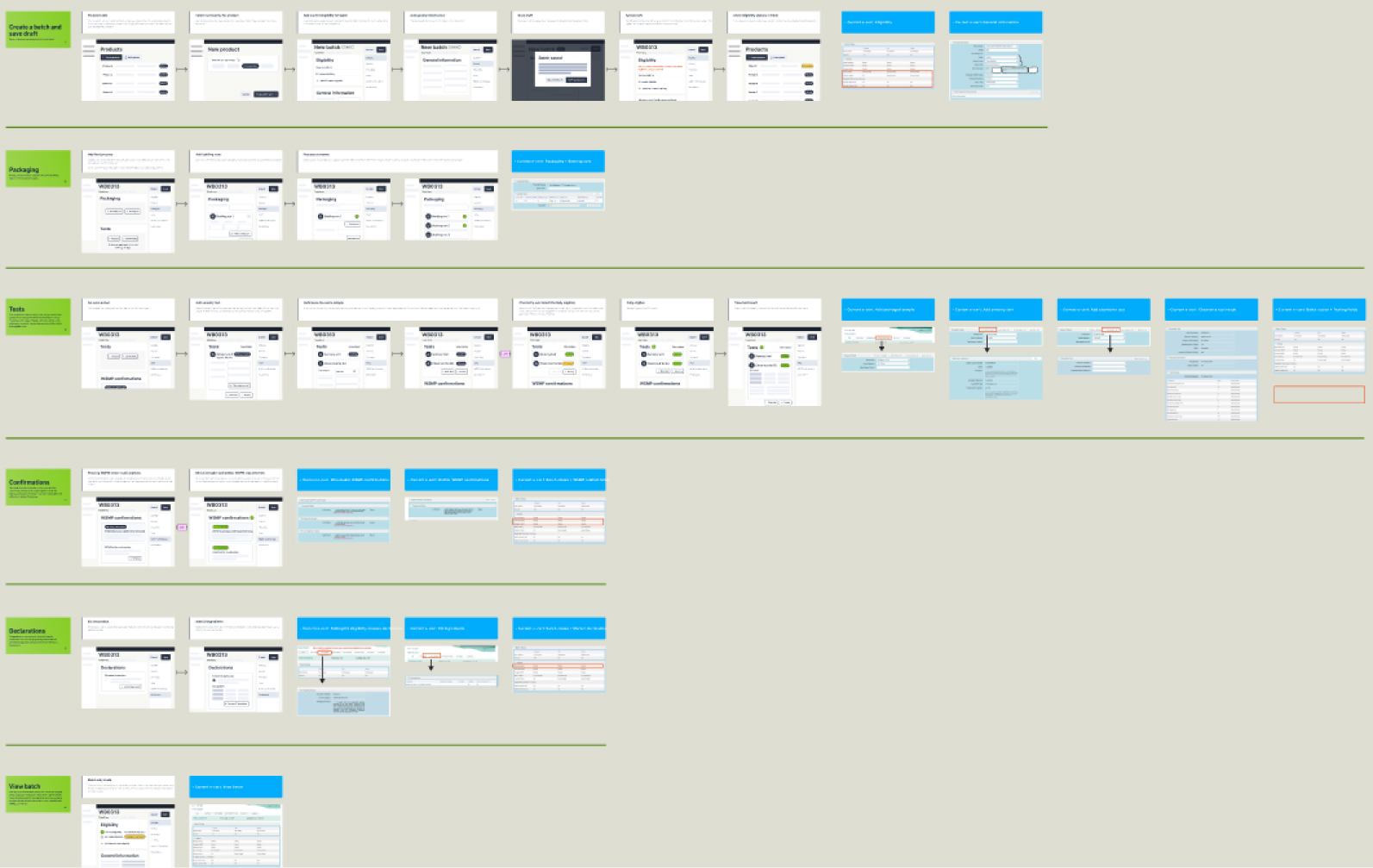

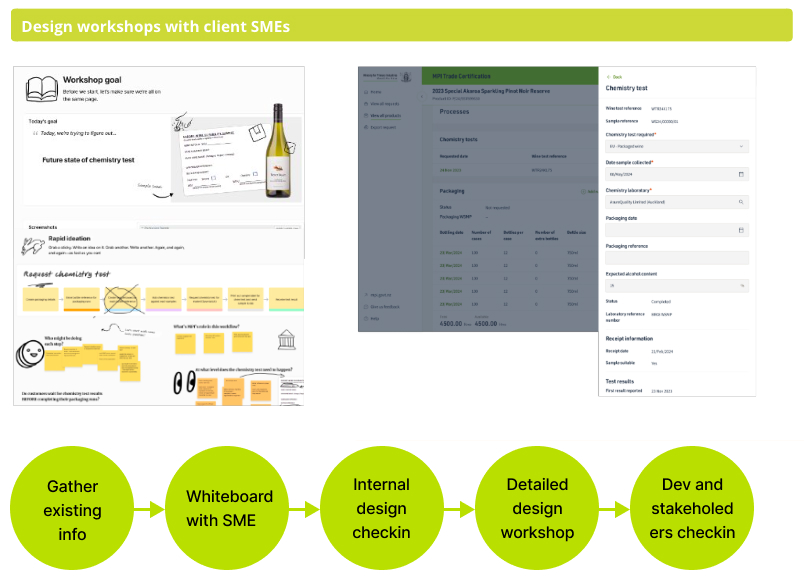

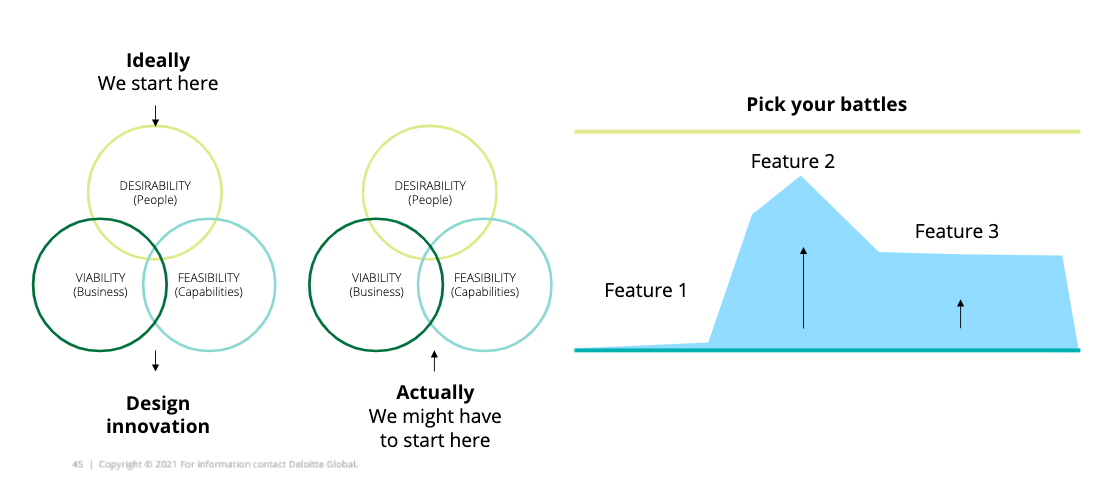

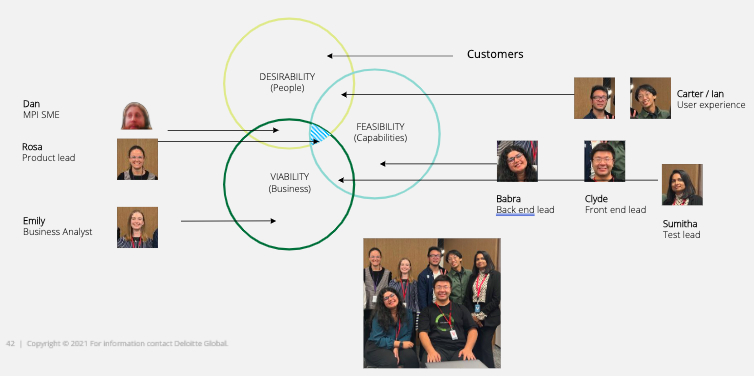

Excel sheets, emails, and PDFs create a mix of confusion, double-handling, rework, and delays. One exporter told us, "I spend more time figuring out how to certify than getting the product ready." MPI knew this had to change. The system is used daily by 10,000+ businesses and underpins over $50 billion of national GDP each year. They partnered with Deloitte to reimagine their export certification system and enhance the exporter experience.